Why is Boiler Water Treatment Important for Efficiency and Safety?

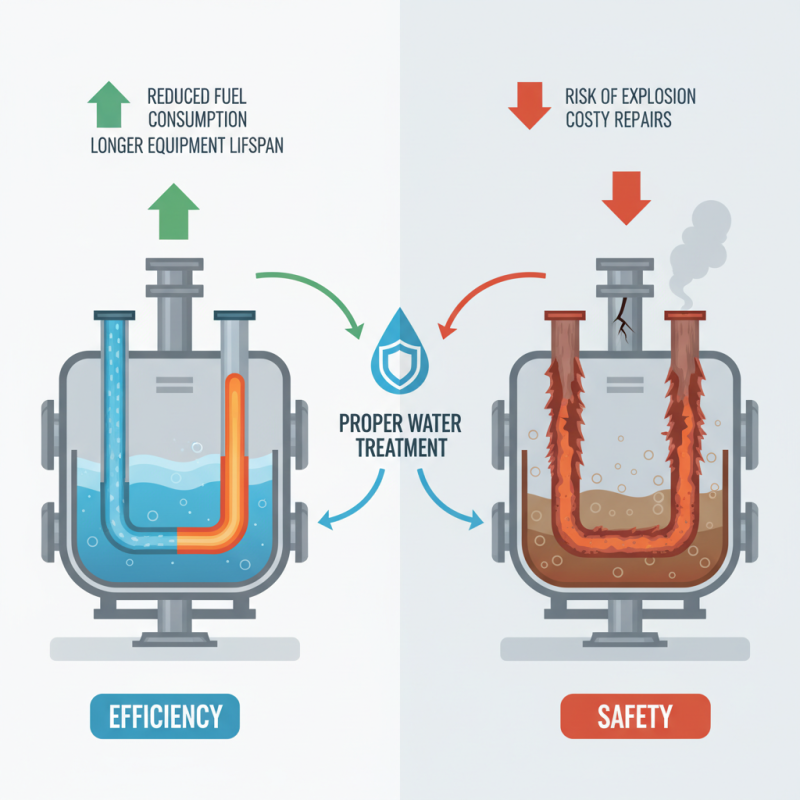

Boiler water treatment is crucial for the efficiency and safety of heating systems. Proper treatment helps prevent scale build-up and corrosion in boiler tubes. These issues can lead to operational failures and costly repairs.

Ignoring boiler water treatment can result in severe consequences. For example, the presence of oxygen and minerals can corrode metal surfaces. This degradation compromises efficiency and can shorten the lifespan of equipment.

Ultimately, effective boiler water treatment promotes a safe working environment. It minimizes the risk of hazards such as steam explosions. Failing to prioritize this aspect of system maintenance invites inefficiencies and significant risks.

Importance of Boiler Water Treatment in Industrial Applications

Boiler water treatment is critical in industrial applications. It ensures safe and efficient operation. The presence of impurities can lead to corrosion and scaling. Over time, these issues can significantly reduce boiler efficiency. This can result in higher fuel costs and unplanned downtime.

Regular testing of boiler water is necessary. Monitoring pH and conductivity helps maintain optimal conditions. Some tips for effective treatment include using chemical additives to prevent scale. Also, ensure proper blowdown practices to reduce solids concentration. Regularly check that equipment is functioning correctly. Neglecting these practices can lead to unexpected failures.

Training staff on boiler water management is essential. Employees should understand the importance of maintaining water quality. They need to recognize warning signs of problems. This awareness can prevent costly repairs. By focusing on consistent treatment and monitoring, facilities can enhance safety and efficiency.

Boiler Water Treatment Importance in Industrial Applications

Understanding the Chemical Processes in Boiler Water Treatment

Boiler water treatment is crucial for maintaining efficiency and safety. Understanding the chemical processes involved is essential. These processes include chemical dosing, pH control, and the removal of impurities. Proper treatment can reduce scaling, corrosion, and foaming, which can lead to system failures.

Here are some tips for effective boiler water treatment. Regularly test water quality to identify impurities. Use appropriate chemicals to control pH levels. Inadequate pH can corrode metal parts. Monitor the system for surprises like unexpected pressure spikes or strange noises. They may indicate underlying issues.

Another point is that treatment isn't a one-size-fits-all approach. Different boilers may have unique requirements. Consult professionals to tailor a treatment plan. Frequent adjustments might be necessary. Skipping these can have dire consequences, leading to downtime or dangerous conditions. Stay proactive in your water treatment strategy.

Why is Boiler Water Treatment Important for Efficiency and Safety?

| Parameter | Ideal Range | Impact on Efficiency | Impact on Safety |

|---|---|---|---|

| pH Level | 10.5 - 11.5 | Prevents corrosion of boiler components | Reduces risk of system failure |

| Total Dissolved Solids (TDS) | Less than 3000 ppm | Maintains thermal efficiency | Minimizes scaling and fouling |

| Oxygen Content | Less than 0.05 mg/L | Enhances heat transfer efficiency | Prevents corrosion damage |

| Hardness | Less than 1.0 mg/L | Reduces scale buildup | Decreases risk of boiler tube failure |

| Silica | Less than 150 ppm | Improves boiler life | Ensures safe operation at high pressure |

Effects of Poor Water Quality on Boiler Efficiency and Longevity

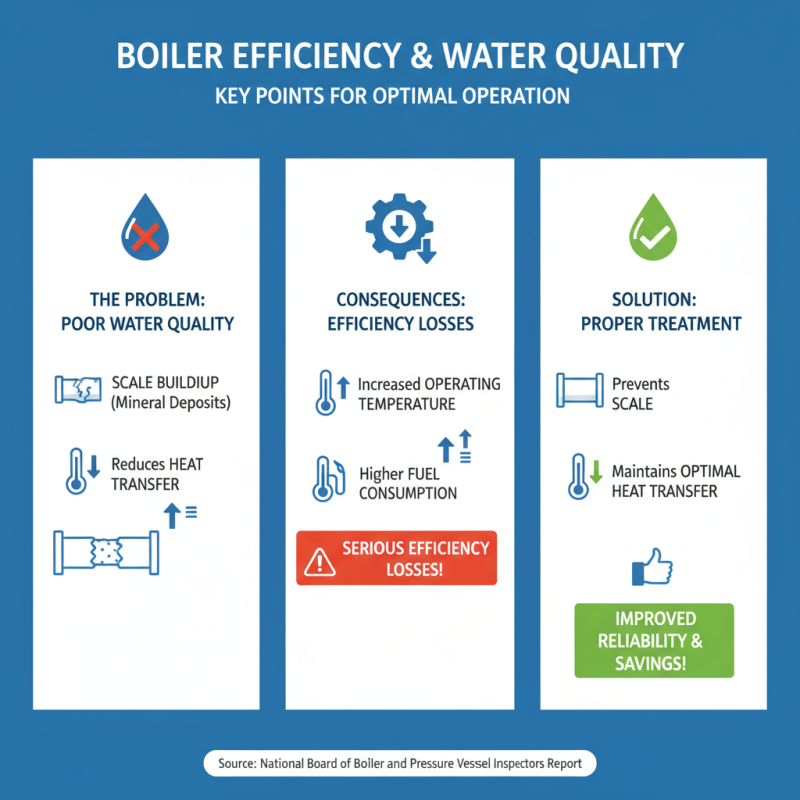

Boilers rely heavily on water quality for optimal operation. Poor water quality can lead to serious efficiency losses. According to a report from the National Board of Boiler and Pressure Vessel Inspectors, improper water treatment can cause scale buildup. This buildup reduces heat transfer efficiency. A boiler's operating temperature can rise significantly due to scale, increasing fuel consumption.

Moreover, corrosion can be a severe issue. A study by the American Society of Mechanical Engineers (ASME) found that boiler corrosion can reduce longevity by over 40%. This damages components, leading to costly repairs. Unexpected shutdowns can occur, affecting production schedules.

Maintaining water quality is not just an option; it is essential. Effective treatment prevents issues that compromise safety. Regular monitoring and adjustments are necessary to keep water quality in check. Operators must stay vigilant. It's a challenge, but it pays off in the long run.

Safety Risks Associated with Neglected Boiler Water Treatment

Neglected boiler water treatment poses significant safety risks. Studies show that improperly maintained boiler water can lead to metal corrosion and scale buildup. According to a report by the National Board of Boiler and Pressure Vessel Inspectors, nearly 80% of boiler failures are related to improper water treatment.

Corrosion can weaken boiler components. This often leads to leaks or even catastrophic failures. Scale formation reduces heat transfer efficiency. Over time, this can cause overheating and subsequent failure. The consequences are not just costly repairs. Safety hazards for workers and potential environmental impacts can arise.

To mitigate these risks, regular monitoring of water quality is crucial. Checking pH levels and hardness regularly can save you major headaches down the line. Don't ignore alarms or warning signs. These are your first indicators that something is amiss. Establish a routine maintenance plan tailored to your specific boiler system for optimal performance.

Best Practices for Maintaining Boiler Water Quality and Treatment Systems

Maintaining boiler water quality is vital for operational efficiency and safety. Regular testing helps detect issues early. Proper chemical treatment prevents scale buildup and corrosion. This ensures a longer lifespan for the boiler. Tools such as conductivity meters and pH testers can provide immediate feedback on water condition.

Adopting best practices is crucial. Following the treatment guidelines can mitigate issues caused by impurities. It’s important to monitor levels of dissolved solids and maintain the correct pH balance. Failing to do so may lead to efficiency losses or unsafe operating conditions. Additionally, regular blowdown procedures are necessary. They help to remove sludge and other contaminants that accumulate in the system.

Challenges may arise when handling different water sources. Variability in mineral content can complicate treatment. Operators must constantly learn and adapt their approaches. It’s a process of trial and error to find the most effective methods. This ongoing engagement is essential to ensure safe, efficient boiler operations.

Related Posts

-

What is a Conductivity Meter and How Does it Work?

-

Top 10 Best PH Meters for Water You Should Consider?

-

2025 Top Conductivity Meters for Accurate Water Quality Measurement

-

Best Home Water Test Kit How to Choose the Right One?

-

How to Choose the Best Tap Water Test Kit for Safe Drinking Water

-

Ultimate Guide to the Best Professional Water Test Kits for 2025