How to Achieve Effective Boiler Water Treatment for Efficiency?

Effective boiler water treatment is crucial for maintaining system efficiency. Proper treatment enhances performance and extends equipment life. It involves managing water quality to prevent issues like scaling and corrosion.

Many operators overlook the importance of regular monitoring. The right chemical balance is essential. Inadequate treatment can lead to costly repairs. Improper management of boiler water can decrease efficiency significantly.

Identifying the right treatment methods is not straightforward. Each system has unique requirements. Operators must reflect on their practices periodically. Improving boiler water treatment is an ongoing process, requiring diligence and adjustment.

Understanding the Importance of Boiler Water Treatment for Efficiency

Boiler water treatment is crucial for efficiency. Many overlook its importance. When water quality suffers, boilers can accumulate scale and corrosion. This can lead to reduced efficiency and increased energy costs. Monitoring water chemicals can prevent these issues. Regular checks are essential.

Understanding the correct treatment methods is vital. Many facilities struggle with inconsistent water chemistry. They may not test frequently enough or misinterpret data. This inconsistency can lead to severe inefficiencies over time. Implementing a dedicated routine can enhance boiler performance significantly. Simplified processes can make this achievable for all.

Visualizing the impact helps grasp its importance. Imagine a boiler working with clean water. It heats evenly, avoids overheating, and saves energy. In contrast, a poorly treated boiler struggles. It wastes resources and increases operational costs. Investing time in proper water treatment is not just wise; it’s necessary for long-term efficiency.

Boiler Water Treatment Efficiency

Effective boiler water treatment is crucial for maintaining boiler efficiency and longevity. The chart above illustrates the recommended levels of key water quality parameters such as Total Dissolved Solids (TDS), pH level, alkalinity, hardness, and silica to ensure optimal boiler performance.

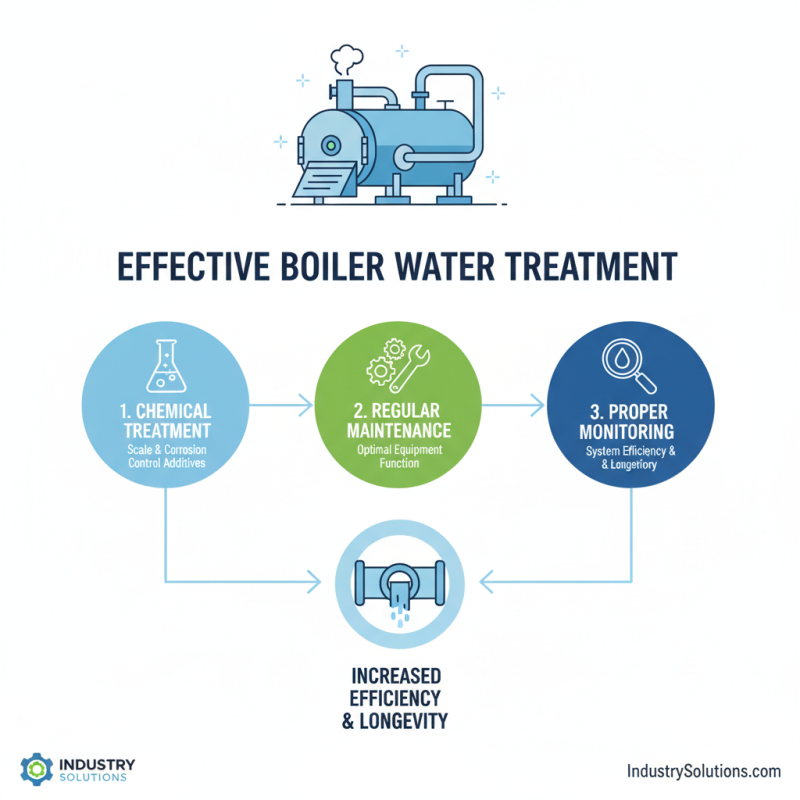

Key Components of Effective Boiler Water Treatment Systems

Effective boiler water treatment is crucial for maintaining efficiency and longevity in industrial systems. The primary components involve chemical treatment, regular maintenance, and proper monitoring. Chemical treatment includes using additives to control scale and corrosion. Regular maintenance ensures that the equipment functions optimally.

**Tip:** Perform routine water tests to identify potential issues. This helps you adjust the chemical treatment accordingly. Don’t wait for problems to escalate.

Monitoring water quality is essential. The concentration of impurities can change rapidly. These fluctuations can lead to efficiency loss. Installing automated monitoring systems could provide timely data. However, these systems can sometimes fail. Manual checks are still necessary to ensure accuracy.

**Tip:** Keep a log of water treatment data over time. This will help identify trends and make better decisions. Reflect on past strategies to improve efficiency continuously.

Step-by-Step Process for Monitoring Boiler Water Quality

Maintaining high-quality boiler water is crucial for efficiency. Regular monitoring is essential. This process can seem tedious, but it is vital to prevent issues. Start with checking pH levels. A pH range of 10 to 12 is ideal. Use simple test strips or a digital meter for accuracy. Regularly conduct this test, ideally every week.

Next, assess the total dissolved solids (TDS). High TDS levels can lead to scaling. This can affect both performance and safety. The recommended limit is usually around 500 ppm. Use a reliable TDS meter for this task. However, remember that fluctuations may occur. If TDS levels are consistently high, investigate the source.

Lastly, watch for corrosion indicators. This requires looking at crystals or cloudy water. These signs can often go unnoticed. It’s easy to overlook minor changes. Regular checks can help catch problems early. Keeping a log of your findings can also guide decisions. Reflection on consistent results can foster improvement in your treatment process.

Common Challenges in Boiler Water Treatment and Their Solutions

Boiler water treatment often faces several challenges. Scale buildup is a common issue. It reduces efficiency and can lead to expensive repairs. Regular monitoring of water quality is essential. Conducting blowdowns can help manage dissolved solids. However, many operations overlook this step.

Corrosion is another significant concern. It can damage boiler components and lead to leakage. Using appropriate chemical treatments can mitigate corrosion risks. Still, achieving the right balance is tricky. Too much chemical can cause new problems, like foaming. Operators must constantly evaluate their treatment protocols.

pH levels fluctuate unpredictably. Maintaining optimal levels is not always straightforward. Inconsistent monitoring can lead to unexpected issues. Implementing detailed log systems may help identify patterns over time. Regular crew training can also enhance awareness and compliance. Inadequate training can compromise system integrity. Regular review of procedures is vital for continuous improvement.

Best Practices for Maintaining Optimal Boiler Performance and Longevity

Boiler performance and longevity hinge on effective water treatment practices. Regular monitoring of water quality is essential. An industry study shows that improper treatment can lead to up to 20% efficiency loss. Scaling and corrosion are common issues that affect heat transfer and equipment lifespan.

Tips: Regularly test water for hardness, pH, and dissolved solids. This ensures optimal conditions for your boiler.

Monitoring chemical levels is crucial. Maintain proper parameters like alkalinity and silica to prevent damage. Over time, neglecting these factors can lead to costly repairs and equipment failures. It’s important to recognize that even minor oversights can escalate into major problems.

Tips: Schedule routine cleaning and maintenance. This helps in identifying potential issues before they become significant.

Your boiler’s efficiency depends on consistent practices. Educating staff on the importance of water quality can create a proactive maintenance culture. Regular training can foster awareness and help minimize errors. Addressing these areas enhances both performance and durability, yet many operations often overlook them.

Related Posts

-

What is a Water Test Kit and How Does It Work for Home Testing

-

Top 5 pH Meters for Water: Accurate Testing for Optimal Water Quality

-

How to Use a PH Tester for Accurate Soil and Water Testing

-

Best Water Testing Kits for Well Water to Ensure Safe Drinking Water

-

Understanding Chlorine Dioxide Formula: Uses, Benefits, and Safety Measures

-

Why You Should Use a Water Quality Test Kit for Safe Drinking Water